Ordering parts from a machine shop can be a complex process, and if you’re not careful, you could run into problems. Before you ask a machine shop to provide a quote and make your part, be sure to check everything. Not sure what to check? I have some advice to consider before finalizing your design and placing an order.

Why should you consider my tips? I own Futuristic Custom Machining which has been custom fabricating parts for the local businesses since 1993. We use subtractive processes such as CNC machining, milling, boring, and CNC lathes. We have more than 25 years of experience making parts for just about any application you can imagine. We have learned quite a bit about working with both novice and experienced designers and machine repair, and have used this knowledge to create an ordering process that minimizes the chance of something going wrong. Give me a call, we go so far as to offer you a review for machinability and potential price reductions.

So what do we at Futuristic say are the 8 most important things to check before pulling the trigger and placing an order with any machine shop?

1. Specify your tolerances

Specifying tolerances correctly is an incredibly important step of making sure the part that’s being manufactured will work as intended. Tolerance is just a way of specifying a range for a measurement, so 1.000 +/- .005 would be the same as saying .995 to 1.005. Although tight tolerances may not be required in many cases for an artist, if your project requires precision and exactness, setting tolerances correctly is immensely important to ensure your part will function correctly.

Another reason to pay close attention to tolerances is that they have the ability to significantly impact the final cost of production. For example, if you submit a design with general tolerances of +/- .010″ (ten-thousandths of an inch),or fractional (5/8”),such a part might be made cost effectively using a water jet or Laser cut. But, if the tolerances for that same part were set to +/- .002 (two-thousandths of an inch) it might need to be CNC milled — which is usually a more expensive process. In other words, a small change to tolerances may lead to a large price change. So use tight tolerances only when necessary.

2. Specify surface roughness

Surface roughness specifies the height of the peaks and valleys of the surface at the microscopic level. To minimize cost use the highest number you are willing to accept. For example, Ra125 is usually economical for machined parts, but if you want a smoother surface consider Ra63 or even Ra32. To get into a really ground range you may need to go down to Ra16 or less. Having finish marks on drawings helps us to determine what your trying to achieve in your part.

3. Choose the right material

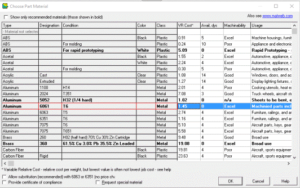

Choosing the right material seems like it would be easy enough, but there are a few things that should be considered to help further reduce production cost.

Makers often think ordering steel parts is cheaper than aluminum because steel costs less per pound. But this disregards the variable of machining time. Aluminum alloys are ordinarily between three to four times less dense than steel alloys, meaning aluminum is much easier to machine, resulting in less wear on machine tools.

Of course, there are numerous other metals and plastics, each with their own unique set of properties.

4. Be flexible with your material choice

Another consideration when ordering a custom part from a machine shop is that the particular material requested might not be on hand at the time of your order. If your application allows for flexibility, consider extending it to the shop producing the part to reduce both cost and delivery time. So if Aluminum 6061 or Aluminum 5052 will do, let the machine shop know!

5. Understand the manufacturing process when designing

If you are new to custom part design, or more familiar with 3D Printing, you really have to think about how the part will be made while you are designing it. Failing to consider the manufacturing process can significantly increase production costs.

Futuristic Custom Machining Manufactured Enclosure and Lid with Rounded Inside Corners

Futuristic Custom Machining Manufactured Enclosure and Lid with Rounded Inside Corners

One of the most common examples of this is seen in the inside corners of custom enclosures. Although it is possible to create sharp inside corners, it’s not practical in conventional machining because a spinning cutting tool creates the corner. Producing CAD drawings really helps the programming of the parts.

6. Be prepared to pay for one-off parts

After designing your part, it is often a good idea to have one or two prototypes manufactured, especially if your future plans include larger scale production. But keep in mind that although machines can make parts effortlessly, there’s quite a bit of labor required to program and set up that machine to work its magic. So even if a CNC mill can cut your part in 5 minutes, it might take significantly longer to set up. And this is why orders for just one part can seem expensive.

The cost to set up a machine to make your part is divided by the number of parts you’re making. For example, a part design with a combined material and machining cost of $1, and a setup cost of $100 will cost $101 per part. But if you’re making 100 of them, the parts would only cost $2 each!

7. Don’t assume anything!

With so many variables in play there’s always a chance that things may not go as planned. So make sure you specify everything that you need to specify, and leave no room for interpretation. Murphy’s law does not make exceptions for custom part fabrication.

8. Knowing the whole picture.

Often machine shops don’t see the whole picture. An assembly drawing, a site visit, or talking to the end user, makes our job much easier before the machining process starts. This is especially helpful in the case of machine repair parts. A machine shop that is willing to make a site visit prior to pricing a custom repair piece can often minimize your machine downtime, help ensure the part will fit the first time, and they may provide suggestions that will lower the part price or even suggestions to make the repair / installation easier.

Whether you plan to work with Futuristic Custom Machining or another machine shop, do yourself a favour and review this guide before submitting your design. These 8 tips will likely save you time, stress, and money!